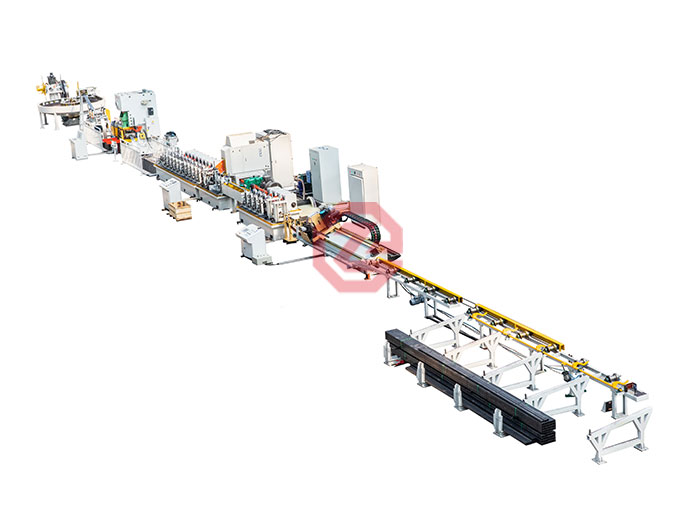

| No. | Item | Unit | Parameters | |

| 1 | Suitable material | Type | black hot rolled steel etc | |

| Strength | MPa | ≥235Mpa | ||

| Thickness | mm | 1.5mm—2.5mm | ||

| Coil internal diameter | mm | 508mm | ||

| Coil weight | T | 5T | ||

| 2 | Specification | mm | 40*50mm | |

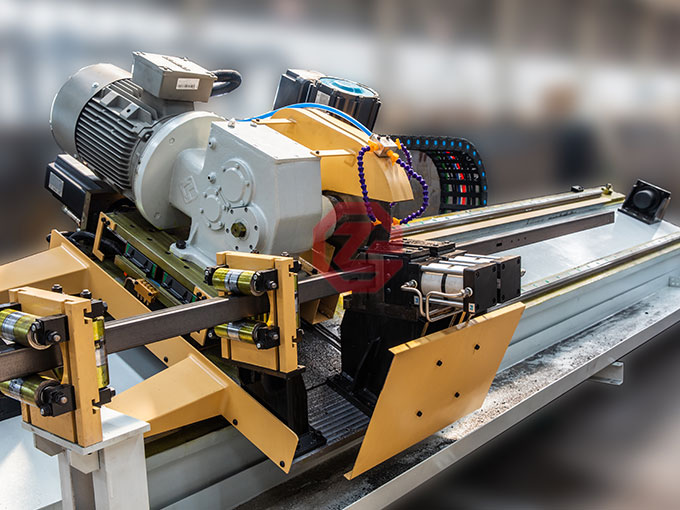

| 3 | Line speed | m/min | 20m/min | |

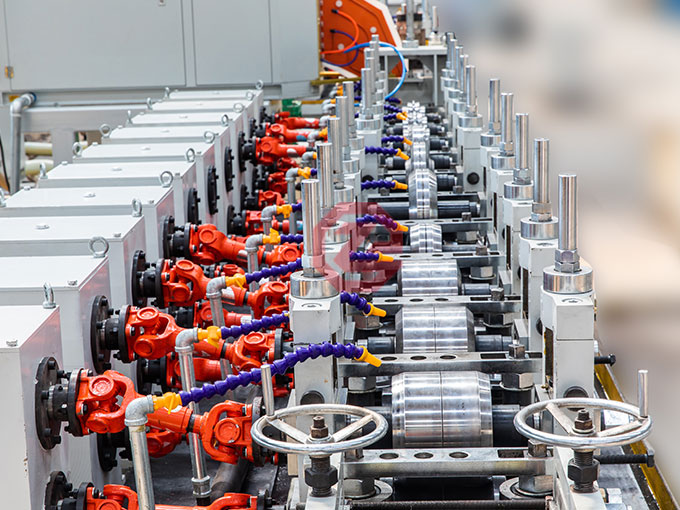

| 4 | Roller material | D2 quenching treatment | ||

| 5 | Roller driven type | External chain transmission | ||

| 6 | Operating system | Windows2000 | ||

| 7 | Total motor power | KW | About 183KW | |

| 8 | Electric control system | PLC automatic control system | ||